ScratchLink is an educational WIFI robotics and coding system suitable for Primary & Up. WIFI browser based coding with live code execution and real time sensor data. Integrated Gamepad functionality for extra fun. Code with Blocks or Script (Javascript/Python/C++). Compatible with all devices (PC, Mac, iPad, iPhone & Android) with no software or updates to install. Three levels of inbuilt robotics challenges plus our Virtual Robotics Simulator.

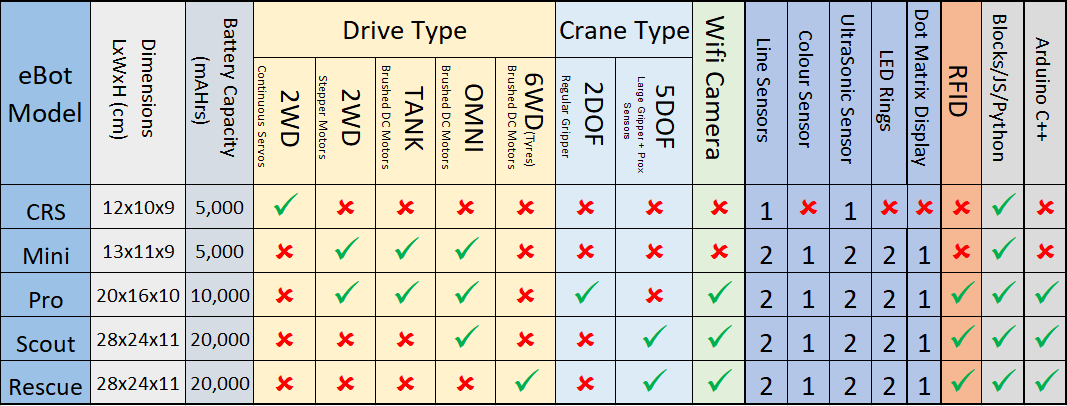

We design and manufacture a range of robust educational robotics including mobile robots, cranes and sorting conveyers etc. Our mobile robots have large rechargeable batteries with on board USB charging that provide a full school day of use. Options include 2WD, Tank and Omni drive plus tough all metal crane arms, RFID, claw proximity sensors and WIFI camera. Standard on all our mobile robots (except Junior) are 2x line sensors, 2x ultrasonic range finders, colour sensor, 2x colour LED rings, 16×16 Dot Matrix display.

Our eBots are now utilised for VET in Schools contact Skills Generation for details.

ScratchLink has been developed by a Queensland STEM classroom teacher, over the last decade, through teaching STEM robotics and Digital Technologies. Always looking for ways to improve the experience for both teachers and students through custom hardware and software. Helping educators and beginner students with classroom coding and robotics has long been a focus.

Scratchlink hardware is designed and manufactured in Queensland, Australia (ABN40294591583) (except for the PCB and electronic components). ScratchLink software is Australian made by our small team of developers.